Free Technical Downloads

Product Overview

- The M257 is a medium frame sized, hydraulic bushing gear motor with high pressure capabilities.

- The M257 series gear motor is built from cast iron ensuring a strong and long lasting product, which can stand the most robust applications. Single & multiple units are available as per your requirements.

- The pressure loaded wear plates of the motor, provides you with a high efficient product.

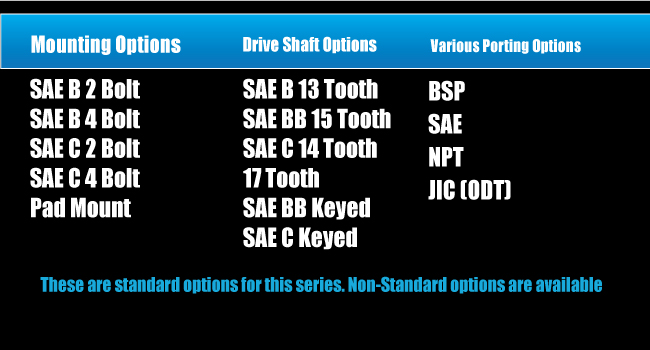

- A wide range of configurable mounting, shaft and porting options are available to suit your unique requirements.

- Compatible with Mineral Oil, Water Glycol, Invert Emulsion & Fire Resistant fluids.

- Spare parts available from stock, such as seal kits, flanges, shafts and individual motor sections enabling a fast turnaround for you if required.

Our Service to you

- We machine, build from stock and test the M257 gear motoron site, to ensure the highest quality and a workable product is delivered to you. The M257 gear motor also comes with a 12 month warranty.

- In the event your product breaks down in the first 12 months, please CONTACT US so we can discuss the best option for you.

- In the event of an emergency or you have a machine breakdown; we can supply this product to you with a 24 / 48 turnaround.

Common Applications

Customers of ours have used this gear motor in applications such as:

- Cranes

- Refuse Trucks

But can be applied to a wide range of mobile machinery within a variety of industries.

ATEX Information

The M257 can be supplied as an ATEX gear motor if required. ATEX Group I & II approval is required, if the product will be used in potentially explosive atmospheres.

ATEX gear motors are ideally suited for applications in the mining, oil & gas industry.

Mounting, Drive Shaft, Porting Options

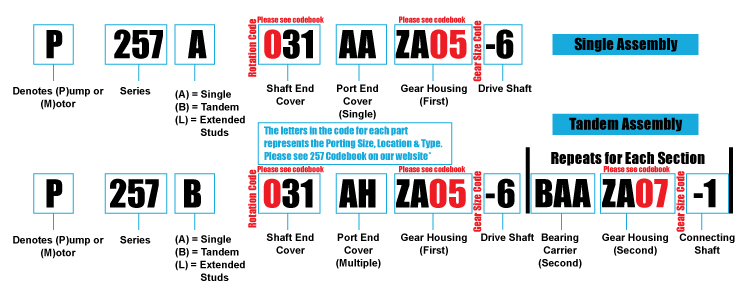

Product Coding Example

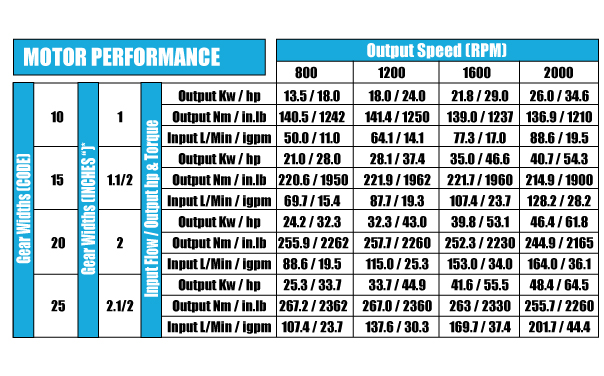

Pump Performance

Recommended Operating Conditions

- Fluid viscosity, normal operating conditions 9 - 220 cst.

- Fluid temperature should not exceed 82 deg C for mineral oil or 57 deg. C for water glycol.

- Fluid cleanliness, 10 micron filter with Beta 200 rating is recommended.

- Inlet pressure; for best operation with mineral oil, pressure should not exceed minus 0.237 BAR (7 in HG) or with water glycol, minus 0.101 BAR (3 in HG)

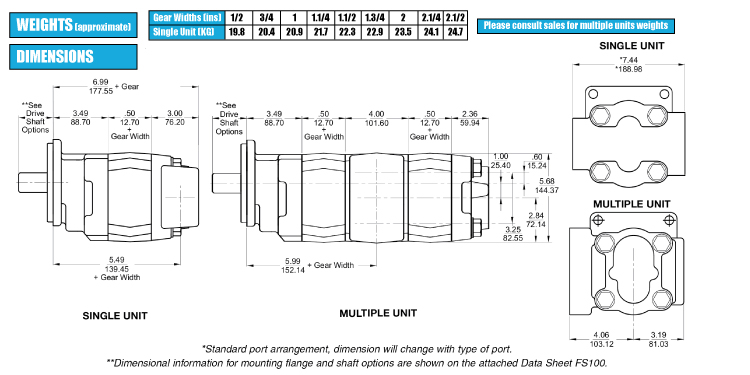

Weights & Dimensions